Supply Chain

Today’s omnichannel customer expectations demand speed, flexibility, and efficiency—yet most supply chains still operate with a split brain: execution happens in ERP/WMS, while planning and analytics sit elsewhere. That separation creates latency, manual work, and recurring firefighting.

Dataviva Supply Chain closes the loop. We combine strategic decision intelligence (forecasting, optimization, policies, what-if) with immediate operational execution—so teams can respond to disruption and demand volatility without escalating effort. Dataviva Supply Chain integrates Order Management with Planning and Execution to remove silos, reduce manual work and increase ROI. At the same time we build optimized replenishment strategy recommendations throughout the entire supply chain.

Our applications are modular: deploy one capability to eliminate a specific pain point, or combine multiple modules into an end-to-end live flow that continuously improves service, cost-to-serve, and working capital.

Because Dataviva is service-based and event-driven, you can add capabilities on top of your existing systems and scale adoption without a multi-year rip-and-replace program.

50%

Reduce Decision Time

25%

Reduce Overstocks

5%

Increase Sales

5%

Increase Margin

Applications

Order Planning & Execution

Purchase orders are where planning meets financial terms and operational constraints. Dataviva converts replenishment plans into optimized purchase order recommendations that respect vendor agreements and constraints—such as volume-based pricing tiers and negotiated terms—while also producing efficient delivery plans that account for order and truck constraints. This reduces manual rework between planners and buyers, improves buying ROI, and accelerates the time from decision to executable purchase orders—without losing governance or auditability.

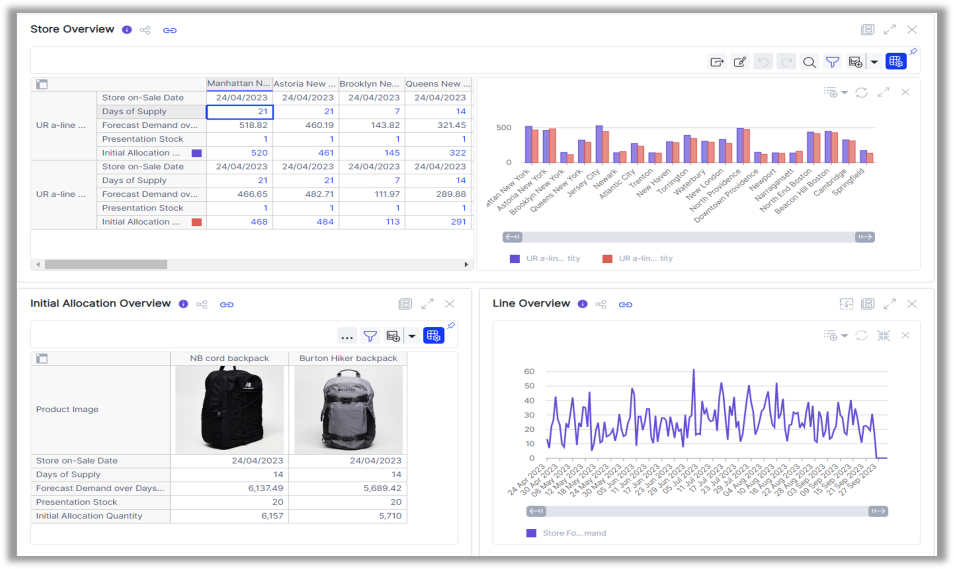

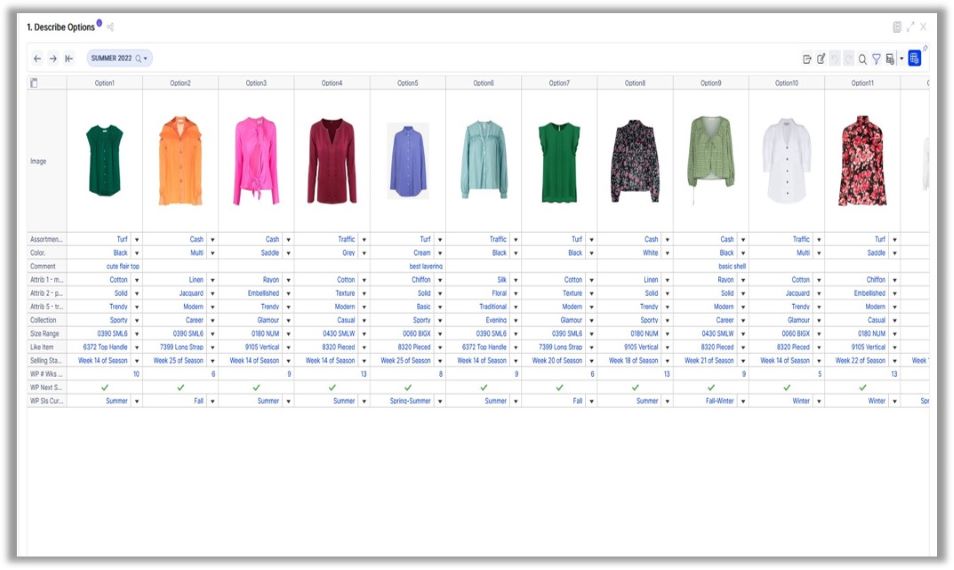

Allocation Planning & Execution

Allocation is where retail strategy becomes reality. Dataviva allocates at SKU level across channels and locations using demand intelligence, assortment intent, and item/location rules, and then keeps allocation current as new signals emerge through the selling cycle. For categories that rely on prepacks, Dataviva accelerates decisions by automating recommendations and determining optimal prepack configurations aligned to warehouse and store requirements. Allocation works as part of the live flow with replenishment—so teams spend less time reconciling and more time improving availability and sell-through.

Automated Replenishment

Manual replenishment processes do not scale under omnichannel complexity. Dataviva generates need-based, time-phased replenishment recommendations across the supply chain, providing unified views of constrained and unconstrained plans and proactively surfacing disruptions before they become stockouts. Replenishment policies are optimized to achieve the right trade-off between service level and inventory cost, with governance built in: approvals, exception-based management, and inventory ringfencing where availability is critical. The system keeps execution aligned to the live plan—reducing drudgery, stabilizing operations, and improving turnover.

Strategy Optimization

Most supply chains operate with replenishment parameters that are too generic, too stale, or too manually maintained to reflect real demand behavior. Strategy Optimization assigns the right replenishment strategy at the item/location level—balancing inventory, sell-through, and waste targets against service objectives. Teams can evaluate trade-offs with what-if analysis, and Dataviva can automatically group items using attribute logic to scale strategy governance. As an overlay module, Strategy Optimization can continuously tune replenishment parameters—so you reduce working capital and improve service without a disruptive replacement program

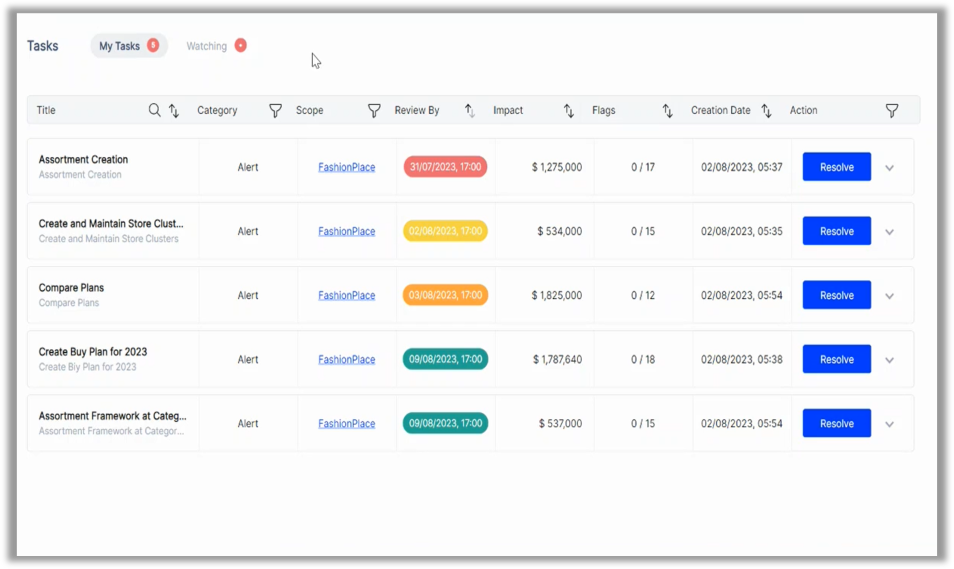

Autonomous Inventory Optimization

Disruptions and demand swings are inevitable; the real cost comes from how long it takes teams to detect them, understand impact, and coordinate corrective actions. Autonomous Inventory Optimization continuously monitors operational signals, identifies disruptions early, evaluates downstream impact, and recommends—or executes—prescriptive corrections within defined guardrails. Instead of asking teams to triage every exception manually, Dataviva prioritizes what matters most and supports consistent, measurable resolution. The result is fewer crises, less ad-hoc effort, and a supply chain that improves through a live loop of sense → decide → act → learn.

Capacity Optimization

Even strong plans fail when physical and operational capacity is ignored. Capacity Optimization aligns delivery and replenishment plans to location-based constraints—reducing handling inefficiencies, improving transportation utilization, and lowering operating cost. Dataviva manages both warehouse and store capacity constraints across categories, enabling teams to smooth flows proactively and avoid last-minute rework when capacity bottlenecks appear.

Supply Chain Monitoring

Visibility is necessary, but visibility alone does not reduce crises. Dataviva provides near real-time monitoring of inventory and sales updates, continuously detecting disruptions and quantifying likely impact with drill-down analytics in context. Crucially, monitoring is connected to the live execution loop: the platform does not just show issues—it guides teams to the next best actions and measures whether the corrective actions worked, improving decision quality over time.